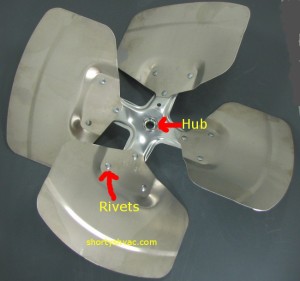

The condenser fan blade should be examined for signs of stress cracks. The most common place for the blade to develop stress cracks is around the rivets where the blades are attached to the hub. The blades are usually made out of aluminum and can flex during operation. If you see a hair line crack extending out from the rivet the blade should be replaced before the crack extends. The blade may flex and hit a bracket or copper line and can gouge a hole in the copper leading to a very expensive repair.

Another failure issue is the blade slipping on the hub. When this occurs sometimes the blade will make a high pitched whine during operation due to the blade turning slightly slower than the motor.

When you are replacing the fan blade make sure power has been disconnected from unit. Remove unit top and turn upside down for access to the blade. Remove lock screw in blade hub and soak hub with penetrating oil. Sand off any rust on the motor shaft. Hold the motor shaft between the fan blade hub and motor with a pair of pliers and gently rotate the blade on the shaft. Pull the hub away from the motor while rotating the blade on the shaft. When installing the new blade make sure the locking screw is tightened down on the flat spot on the shaft. this is very important.